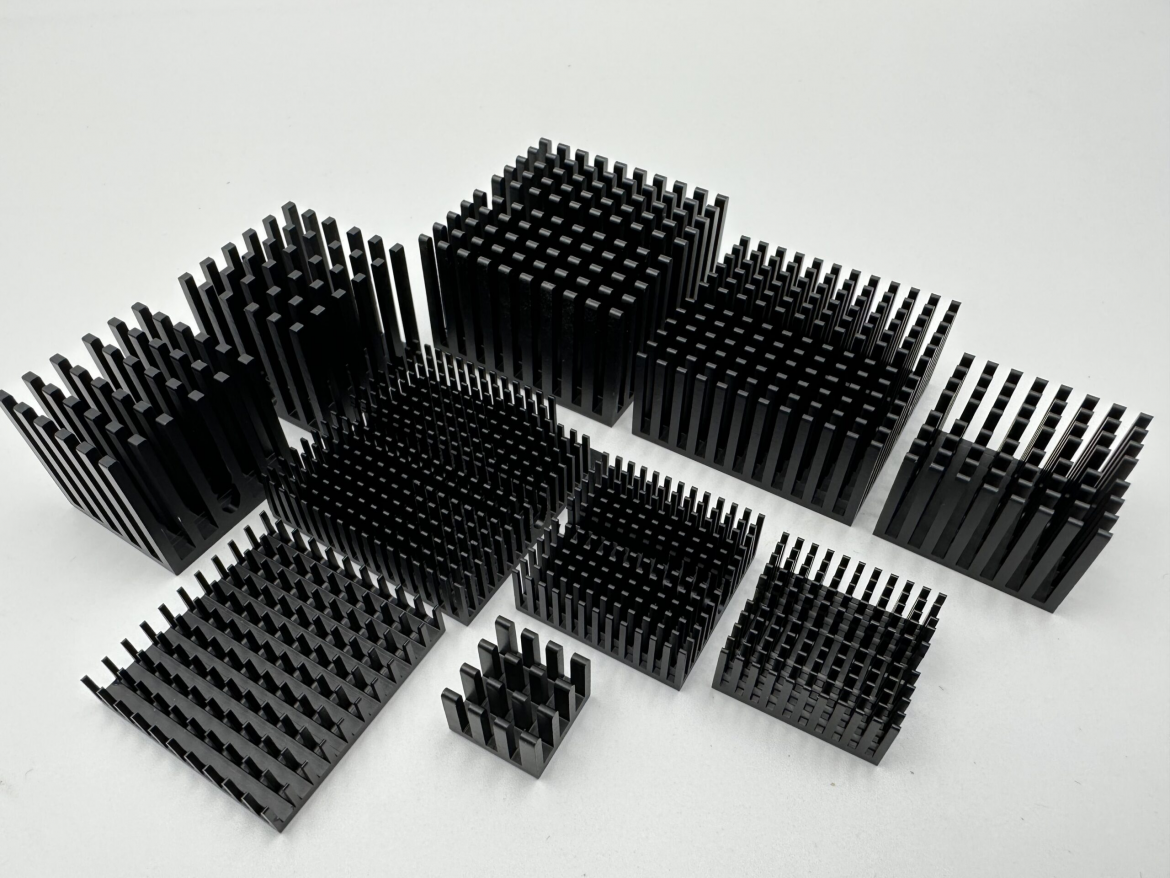

In high-performance electronic systems, thermal control plays a decisive role in ensuring long-term stability. Power ICs, FPGAs, and high-TDP chipsets generate significant heat during continuous operation, and effective cooling becomes essential. When discussing compact thermal solutions for these components, BGA heatsink designs often emerge as a practical and reliable option. A BGA (Ball Grid Array) heatsink is a compact thermal device created specifically for BGA-packaged components widely used in CPUs, GPUs, chipsets, and FPGAs. These solutions fit restricted layouts and help maintain proper temperatures by directing heat away from the chip surface. As a manufacturer in the mechanical and thermal field, Dingmetal is recognized for supplying structural parts that support consistent quality and dependable thermal performance. Their experience helps buyers and R&D engineers assess the suitability of different thermal modules for demanding applications.

Practical Benefits of BGA Cooling for Power ICs

Power ICs are especially sensitive to temperature fluctuations, and stable output depends heavily on consistent heat dissipation. Integrating BGA heatsinks into these circuits helps limit temperature spikes and reduces the risk of thermal-related drift or failure. These heatsinks maintain an efficient thermal pathway between the chip and surrounding airflow, allowing the system to operate at its intended performance level. Since Power ICs are often installed in compact power-control boards, a BGA heatsink offers a balanced approach—small enough for tight spaces yet effective enough for continuous power conversion. When engineers evaluate solutions for precision power modules, they often consider manufacturers like Dingmetal, who provide structural components with reliable quality control, punctual delivery, and engineering-oriented support. Their production capabilities allow buyers to source parts that match various assembly constraints and reliability requirements.

FPGA and High-TDP Chipset Cooling in Dense Systems

FPGAs and high-TDP chipsets typically run complex workloads involving parallel processing, real-time data handling, and signal routing. These operations create substantial heat, making thermal solutions a critical part of system design. A well-matched BGA heatsink is beneficial because it manages heat without demanding excessive board area or airflow modifications. As processing density increases, BGA-based designs allow engineers to maintain compact system layouts while still addressing elevated thermal loads. The versatility of BGA heatsinks enables layouts that support both forced-air and passive cooling environments, which is valuable for communication equipment, industrial controllers, and embedded computing. Companies such as Dingmetal serve these sectors with mechanical components engineered for stable assembly performance, backed by structured R&D and service processes that support long project cycles. Their approach helps customers streamline sourcing while maintaining dependable build quality.

Balanced Thermal Strategies for Modern Systems

Choosing proper thermal solutions for Power ICs, FPGAs, and high-TDP chipsets requires understanding heat distribution, material compatibility, and space limitations. A BGA heatsink provides a functional answer for compact, high-density layouts by efficiently transferring heat and supporting continuous system operation. The adaptability of BGA heatsinks makes them suitable for a wide range of electronic architectures where thermal stability is essential. With manufacturers like Dingmetal offering consistent quality, engineering support, and dependable delivery processes, buyers and development teams can incorporate these solutions into projects with confidence, ensuring long-term reliability and performance.